From Maker’s Mark, to Wyoming Whiskey, to Bardstown Bourbon Company

Steve Nally’s more than half-century journey through the bourbon landscape has taken him from humble beginnings in Loretto, to the Kentucky Bourbon Hall of Fame, and ultimately to the pinnacle of his profession.

Steve’s first stop was Maker’s Mark Distillery, where he eventually became Master Distiller, a title he held for 18 years. Next, he went west to build the Wyoming Whiskey, that state’s first distillery. Eventually he returned to the Bluegrass State as the first employee hired to help bring Bardstown Bourbon Company to life. Today he is the Master Distiller of that company which bills itself as “one of the country’s most modern and technically advanced whiskey distilleries,“ and is the seventh-largest distiller of bourbon, rye, and American whiskies in the country.

Steve and his wife Donna are both members of the Kentucky Bourbon Hall of Fame.

Last March, Bardstown Bourbon Company honored Steve with a special dinner celebrating his first five decades in the bourbon industry. I had the honor of sitting down with Steve in his office in the Bardstown Bourbon Company distillery recently. Here is a sample of our conversation about how things are going in his 51st year in the bourbon business.

Tell me about how you how you got into the bourbon business in the first place?

“I grew up right next to Maker’s Mark. Our property adjoined Maker’s Mark’s property. We grew up there. As a child I’d ride my bicycle past the distillery, I played on the distillery property. I’d walk through the woods and hunt on their property. I just was part of it. Thinking back it was, in a way, maybe meant to be. I was born in 1950. T.W. Samuels bought Maker’s Mark in 1953. It had been sitting idle for years and they start cleaning it and started production at some time in 1954. They started very, very small. When I graduated high school, I actually bought a farm, went in debt, and started farming. I did that for almost four years, but farm prices kind of went down, interest rates went up. It got to be really tough because at that time I had a family and I was starting to really get in a pinch. I knew Sam Cecil, the plant manager and general manager. My first job was growing yeast and keeping the yeast culture going.

“I guess I was just adventurous. When a new job came up, I would take it and learn it. Over the first 17 years I actually worked every job down there: maintenance, night watchman, warehouse, you name it. In 1988 they asked me to become master distiller.

“When I was coming up in the industry, it was like a big family. It was people that I looked up to and admired, like Booker Noe, Parker Beam, Jimmy Russell, Elmer T. Lee, all of those people were legends to me. I never imagined I’d be part of that group.”Steve Nally, Kentucky Bourbon Hall of Fame Inductee 2007

On that very first day when you went into Maker’s Mark and asked for a job, did you ever imagine the career that lay ahead of you?

“Oh no. I knew nothing about it. I mean I went in there a greenhorn, you might say, and they told me what to do. You know the importance of yeast. I had no idea that I was holding the whole production in my hands. If I screwed that up, I messed up the whole operation. Sam Cecil was also the chemist. He trained me on the procedure and how important that was to the process. He was also (in the) military and was a very precise guy and that was how I was trained.

Can you tell me what an average day on the job that first year at Maker’s Mark was like?

“At that time, we were only making 30 barrels a week at Maker’s Mark. So, you would go in and maybe Monday you would cook a batch and get it into the fermenter. Then while it was fermenting, you go out and maybe do yard work, or put product in the barrel, or help on the bottling line, or do something else. Then Thursday, fermentation would be complete so you would go back and distill it, then you put it in the barrel, and then you put it in the warehouse. So you did a little bit of everything the first few years I was there. I learned maintenance… if a motor broke down you would help change it out. You really got a lot of experience during those first few years because they were so small. There was only maybe 10 or 12 people there working on everything.

Through three distilleries, what kind of changes have you seen in 51 years in the industry?

“When I first went down there (to Maker’s Mark) everything was manual. There was no automation at all. The fermenters had no cooling. In the summertime, if it got real hot, you didn’t run because you had no cooling water. I remember…bringing in ice to throw in the fermenters to keep them cool. And later putting in the first chillers. If it got too hot, it ruined the fermentation. The first piece of automation we put in was box that controlled the water going in to cool the mash between the cooker and the fermenter.

“I was at Maker’s Mark (in the 1980s) when the bourbon industry went pretty much to nothing, we thought it was going out of circulation. Everyone was drinking clear spirits and nobody wanted bourbon. Now they’re back to bourbon and we can’t make enough of it.

So, did you just say that years ago before all of this automation and technology there were days that it was too hot to make bourbon?

“Yes, because you could not get enough coolant capacity to get it to the temperature you needed to ferment. If you get above about 95-96 degrees yeast will perish. Back when I first started you pretty much had shut-down during July and August because you didn’t have the cooling capacity to run the process.

And that’s when you picked up even more job experiences in other areas?

“Yes, or you got laid off for a little while. A lot of the distillers would shut down for the summertime before chillers came in. Once September came and it started cooling down at night, you could pick back up and run like crazy all winter. But then when it got really cold, you had trouble with pipelines freezing up.

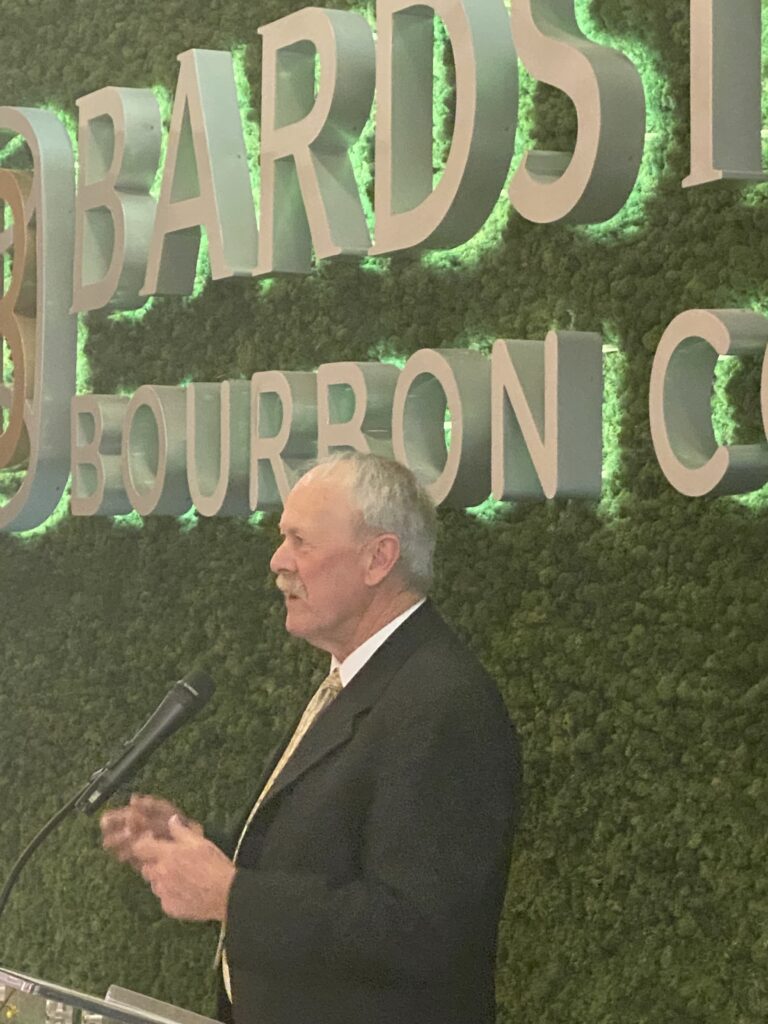

Steve Nally spoke to a gathering of friends and family celebrating his 50 year anniversary in the bourbon industry in March, 2022. (Photo by Brian G. Miller)

I was here for your 50th celebration night. I felt like I’d won the lottery just getting invited, so it must have been pretty special being the guest of honor.

“It was a wonderful time. It really was kind of a milestone I never dreamed of getting to when I started in the industry.

“To see everybody here I was friends with and grew up with in the industry…it was very touching. I’m a very emotional person. I’m normally not a very talkative person and to get up there, to talk and to see everybody, it was very emotional for me.

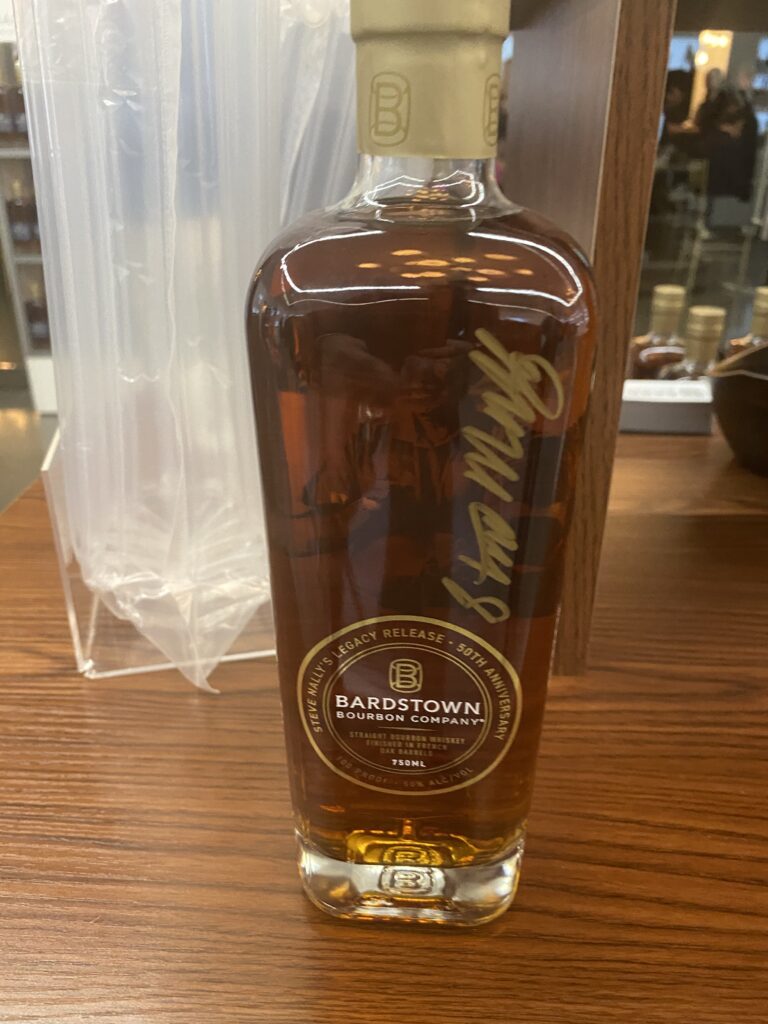

“I developed my Legacy product (note: see box below) and had it there that night. I’m very proud of how that turned out. Not very many distillers have reached that point. I don’t know how many more years I’ve got to do it. But it’s like Donna, my wife, says, ‘He’s going to keep doing it as long as he feels like it.’

“I’m having a good time now with this company (Bardstown Bourbon Company). It’s been a whirlwind to start this process and do custom production. We’re helping out small craft distilleries that probably wouldn’t make it without somebody like us to help.

You met your wife Donna when you both worked at Maker’s Mark. What does it mean to have a partner in a life who understand and shares your passion for the industry so well that she was inducted into the Kentucky bourbon Hall of Fame a few years after you were?

“Donna, in her own right, developed the tourism side of things in the bourbon industry. She helped develop the tour program at Maker’s Mark and was very much a part of developing the Kentucky Bourbon Trail and the Kentucky Bourbon Festival. In 2011 she was inducted into the Kentucky Bourbon Hall of Fame and we’re the only living couple that that’s in the Hall of Fame. The other couple is Bill and Marge Samuels. It is a great honor.

“When I was coming up in the industry you know it was like a big family. It was people that I looked up to and admired, like Booker Noe, Parker Beam, Jimmy Russell, Elmer T. Lee, all of those people were legends to me. I never imagined I’d be part of that group.

“Even when I was the youngster…I was the kid in amongst those giants. I would go to meetings with them, and they treated me like I was one of them. I thought, really? In 1988 (when he was named Maker’s Marks Master Distiller), I’m 38 years old, I’m a nobody. I know nothing. If I needed help, they’d jump in and help you like you worked for their company. It was unimaginable that it was such a close-knit group. We partied together. We worked together.

“One of the most memorable things is the Heaven Hill fire (in 1996). It destroyed their distillery. It burned close to 100,000 barrels of their product. What happened? All the other companies jumped in and either sold them barrels or made product for them. It kept them from going under. The comradery, the fellowship, and the companionship that distilleries have to help each other out still exists today. Now, it doesn’t exist out in the marketplace!

“Donna, in her own right, developed the tourism side of things in the bourbon industry. She helped develop the tour program and Maker’s Mark and was very much a part of developing the Kentucky Bourbon Trail and the Kentucky Bourbon Festival.

Steve Nally

What does it mean to have the title, Master Distiller and how has that evolved?

“When I first took the position, (at Maker’s Mark) I was head distiller. When we started having tastings, seminars, and things like that, we were deemed master distillers. But there is one drawback to that now. Every distillery that starts up today will name somebody a master distiller, but there needs to be some formality to it. In my situation, I earned that (title) by working my way up to it.

“Some distillers come in and earn their way up by formal education, say with a chemical degree, and have worked in the distilling industry for a while. If you start a company and you’ve been in the distilling industry for two years and deem yourself a master distiller, then you really haven’t worked your way into it. There’s not too many left in the industry that got their title the way I did. Okay, I’ve done my spiel on that!

What prompted your moved from Maker’s Mark to the opportunity in Wyoming?

“The reason I left Maker’s Mark is we were bought out. We’d actually been bought out a couple of times. Bill Samuels said if we’re going to be bought out, we’re going to keep running things the way we’ve been running them. The last time, they changed some of the benefits. I was the last one to retire with all the benefits in place.

“I left Maker’s Mark and actually drove a semi for four years. I delivered grain to distilleries and stayed in touch with everybody. In 2007, three attorneys came to one of the Bourbon Festivals and wanted me to come to Wyoming and build the first distillery in that state. I was thinking, ‘I can go all the way out there and nobody will know what I’m doing. I can venture out on my own and if I make a mistake, nobody’s going to know it.’ But everybody here was watching what I was doing.

“There were some difficulties: at 4200 feet elevation, the cook temperatures were different; with 20 percent humidity the climate was different. There were a lot of difficulties getting things up and going. I got a good product going. It was going really well until…when the product was 3-and-a-half years old, the owners said, ‘We’re going to release product.’ I said, ‘It’s too early, it’s not ready, don’t do it.’ They said, ‘It’s our company, we can do whatever we want.’ I said, ‘Remember, you’ve only got one change to make a first impression.’ Now that they’re five-years-old, it’s really a good product.

“During that time, Peter Lofton contacted me about starting up here (Bardstown Bourbon Company). I came here and started this adventure in 2014 with a custom production process. We started at about 25,000 barrels in September 2016. In June 2017, we doubled (production). In June 2018, we doubled again. We haven’t stopped growing since we first stuck a shovel in the ground. When we finish our current expansion, we’ll have 48 fermenters and three stills and will be at about 250,000 barrels a year.”

What was it like to come back to Kentucky to start up Bardstown Bourbon Company and build something from scratch in a cornfield?

“When I left, everybody said, ‘You’ve done left home and deserted us. When I came back, it was all open arms.’ It was just like, ‘You’re back home now, everything is great.’

“This business has taken off and everyone has been overwhelmingly responsive to it. To grow this fast has just been amazing.

“When we started, I asked them to wait to release our Origin product when it was six years old. At four years, some of them said, ‘It’s getting pretty good.’ I said, ‘No, it’s not great yet.’ At five years, same thing. So now, at six years, we released our Origin product and it’s great.

“We’ve done Collaboration, Fusion, and Discovery series that got our name out there. Now we’ve got our six-year Origin product that we’re very proud of.

Bardstown Bourbon Company has made a major mark in the industry with its creative blending and raising the perception of blending whiskies.

“In the past, blending was always used to cover up something. Canadian and Irish whiskey have been blending for years. But bourbon, traditionally, you blended to cover up a bad product.

“We’re not doing that. We’re blending to take good products and make them even better. Part of our motto from the get-go has been ‘Transparency,’ so people are starting to realize that’s important to us. I think that’s why they’re so responsive to what we do.

At your 50th celebration last year you said you have no plans for retirement. What does a day in the life of Steve Nally look like now?

“I don’t do a whole lot out on the floor anymore. I do interviews like this. I just spent two weeks on the road and stayed in six different hotels. But I enjoy going out and meeting people, talking about our products, and what we do. Some are public events and others are industry meetings. I do bottle signings, pour samples and let people taste our products, and talk about Bardstown Bourbon Company.

Where do you think the bourbon industry is going?

“You always think the production side can’t be refined more. When I started at Maker’s, I didn’t think it could be refined more. But there’s always room for improvement.

“On the visitors’ side, we’re creating more of the Napa Valley experience. Part of that has been made possible by regulations changing. Five years ago, you couldn’t go to a distillery and have the experience you can have now…a great meal and a nice cocktail. We like to think we’re a little better than others, because that experience was built in here from the beginning.

What does the future hold for Bardstown Bourbon Company?

“When we set this building up, Peter’s original plan was to grow into it in 15 or 20 years. And we grew into it in six years. Nobody could imagine the velocity the bourbon industry would grow at.

“I get asked all the time, ‘Where do you think it’s going to stop?’ I don’t think anybody can tell you that. We, Bardstown Bourbon Company, have not saturated the United States yet. We have calls from overseas all the time wanting us over there. We have a lot of growing to do. It’s fabulous to be involved in the industry when it’s at this pace. I know the consumer is overwhelmed with the quality of products available today. If you go in a store, the bourbon shelf used to be 10 feet long and now it’s 100 feet long. It’s quality products on the shelves. I think we’re just going to keep going and growing.

“I like to think Maker’s Mark’s one recipe gave me the basics, the training I needed. It set the foundation for what I’m doing today with 60-plus recipes for Bardstown Bourbon Company. If you’re a 300-barrel customer or a 3,000-barrel customer, we’ll provide you with the same quality.

What does the future hold for you?

“Well, I’m going to keep doing this as long as I enjoy it. Who knows. Right now, I’m enjoying it, and everything is great.”

Cheers to you, Steve Nally for your significant accomplishments during 51 years in the bourbon industry. Best wishes for many years to come.

Steve Nally’s Legacy Release – 50thAnniversary

- Kentucky straight bourbon finished in French oak for 25 days.

- 100 proof/50% ABV.

- Mash bill: 52% 15-year Kentucky bourbon (corn 75%, rye 13%, malted barley 12%),

- 25% five-year Bardstown Bourbon Company bourbon (corn 68%, wheat 20%, malted barley 12%),

- 23% five-year Bardstown Bourbon Company bourbon (corn 60%, rye 36%, malted barley 4%).

This story originally appeared on the cover of the November issue of Whiskey Network Magazine.